Optimizing Efficiency in Every Environment

Heat exchange applications

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Heat exchanger wind turbine

In wind turbine systems, heat exchangers play a crucial role in regulating temperatures, preventing equipment from overheating. This technology enhances the efficiency and longevity of turbines, contributing to more sustainable and reliable renewable energy production.

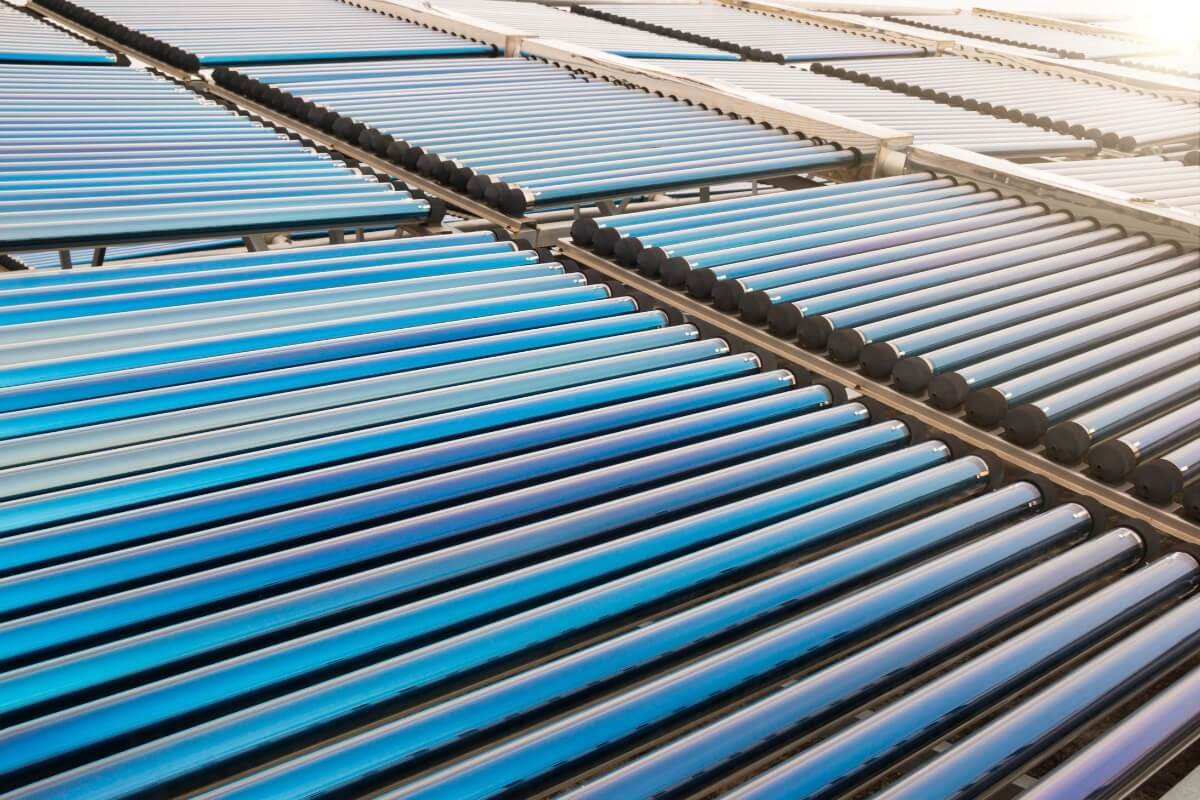

Heat exchanger solar water heater

In solar water heating, heat exchangers are vital for transferring solar energy to water, ensuring efficient temperature control. This sustainable solution contributes to energy conservation, offering reliable hot water supply with minimal environmental impact.

wind turbine cooling system

Wind turbine cooling systems play a crucial role in maintaining the operational efficiency and reliability of turbines. They prevent overheating, ensuring consistent energy production and prolonging the lifespan of turbine components.

Marine heat exchangers

Marine heat exchangers are essential in maintaining engine temperatures, protecting against overheating. Their robust design ensures consistent performance and durability, supporting operational stability in challenging marine conditions.

marine hot water heat exchanger

Discover the efficiency of marine hot water heat exchangers, designed to maintain optimal engine temperature and performance in harsh marine environments, ensuring reliability and longevity for your vessel.

marine oil cooler heat exchanger

Marine oil cooler heat exchangers ensure efficient engine performance, maintaining optimal oil temperatures and enhancing durability in challenging marine conditions.

marine heat exchanger manufacturers

Marine heat exchanger manufacturers specialize in creating systems that optimize engine performance and prevent overheating in harsh marine environments. Their products ensure the longevity and efficiency of marine vessels by providing superior cooling solutions.

Starch drying

Starch drying systems efficiently reduce moisture content in starch products, enhancing their quality and extending shelf life. These systems are tailored to meet the specific drying needs of the starch industry, ensuring optimal performance and reliability in processing environments.

Counterflow heat exchanger

Counterflow heat exchangers efficiently manage thermal energy by allowing fluids to flow in opposite directions, enhancing heat transfer capabilities. This design maximizes temperature gradients, improves energy conservation, and elevates system performance across multiple applications.

Spray drying

Spray drying specialists develop systems that efficiently convert liquid into powder through atomization, enabling precise moisture control and particle size distribution. Their technology ensures consistent product quality and improved preservation, essential for various industries like food, pharmaceuticals, and chemicals.

Heat exchanger oil refinery

Heat exchangers in oil refineries play a crucial role in optimizing thermal transfer processes essential for refining operations. These systems enhance energy efficiency, boost operational effectiveness, and meet the rigorous demands of oil processing, ensuring reliable and sustained performance.

Offshore condenser

Offshore condensers are integral to managing thermal processes in challenging marine environments. These systems ensure efficient heat dissipation, stabilize operating temperatures, and support the continuous operation of offshore installations, contributing to their durability and performance.

Dehumidification coolers

Dehumidification coolers are essential for controlling moisture levels in various environments, efficiently lowering humidity while maintaining desired temperatures. These systems enhance air quality, prevent moisture damage, and improve comfort and efficiency in residential, commercial, and industrial settings.

Infant formula production

Infant formula production involves a meticulous process that ensures nutritional completeness and safety for consumption by infants. The industry utilizes advanced technologies for precision blending, pasteurization, and drying to create formulas that closely mimic the nutritional profile of human breast milk.

Industrial oil cooler

Industrial oil coolers are essential for maintaining optimal temperatures in machinery by efficiently dissipating heat from oil used in manufacturing and processing equipment. Their application is critical in sectors such as automotive manufacturing, plastics molding, and other heavy industries to ensure machinery operates smoothly and to prevent overheating.

Hvac heat recovery system

HVAC heat recovery systems are designed to capture and reuse heat that would otherwise be expelled from buildings, significantly improving energy efficiency. These systems are commonly used in both industrial and residential settings to reduce the energy costs associated with heating and cooling, enhancing overall system performance.

Hvac heating system

HVAC heating systems utilize heat exchangers to warm air that is then circulated throughout buildings, ensuring a comfortable indoor environment. These systems are essential in residential, commercial, and industrial settings for efficient temperature management and air quality control.

Fluid bed drying

Fluid bed drying is a process used extensively in industries like pharmaceuticals, food, and chemicals for efficiently drying powders and granules. It involves suspending and fluidizing the particles in a stream of air or gas, which enhances heat transfer and drying speed.

Cross flow heat exchanger

Cross flow heat exchangers are extensively used in HVAC systems and industrial cooling processes, where they efficiently handle heat transfer between air streams that flow perpendicular to each other. Their design optimizes thermal performance in compact spaces, making them ideal for applications in electronics cooling, automotive radiators, and air handling units.

Thermal oil heating system

Thermal oil heating systems are utilized in various industrial processes for efficient heat transfer at high temperatures without high pressure. They are ideal for sectors like chemical processing, oil and gas, and manufacturing, providing consistent and reliable heat while maintaining system stability.

Air cooled steam condensor

Air cooled steam condensers are essential in power generation and industrial processes where they efficiently condense exhaust steam from turbines without water usage. Their design facilitates effective heat dissipation and condensation, making them ideal for environments with limited water resources.

Cooling system marine engine

Cooling systems in marine engines are essential for regulating engine temperature and preventing overheating in harsh marine environments. These systems utilize seawater and fresh water to efficiently dissipate heat from the engine, ensuring optimal performance and longevity.

Heat exchanger food processing

Heat exchangers in food processing are crucial for efficiently managing temperatures during crucial stages such as cooking, cooling, and sterilization. They ensure product quality and safety by maintaining precise control over heat transfer, critical in applications like pasteurization and fermentation.

LNG heat exchanger

LNG heat exchangers are crucial in the liquefaction process of natural gas, efficiently cooling and condensing gas into liquid form for easier storage and transport. They also play a key role in regasification terminals, where they warm the LNG to convert it back into gas for distribution and use.

Marine dry coolers / offshore dry coolers

Marine dry coolers and offshore dry coolers are specifically engineered for the harsh marine and offshore environments, providing reliable and efficient cooling. They are essential for managing heat in equipment and processes where water use is restricted or undesirable.

Titanium air cooler

Titanium air coolers are essential in environments where corrosion resistance and durability are paramount, such as in marine or highly corrosive industrial settings. These coolers efficiently manage heat exchange, ensuring optimal performance in cooling air or gas streams even under harsh conditions.

Milkpowder drying

Milk powder drying involves the removal of water from liquid milk to create a dry, shelf-stable product. This process typically utilizes heat exchangers to efficiently manage the air temperature and humidity, ensuring high-quality and energy-efficient production of powdered milk.

Wind turbine cooling

Wind turbine cooling systems use heat exchangers to manage the heat generated by the turbine's mechanical and electrical components, ensuring optimal performance and longevity. These systems are crucial in maintaining the turbine's efficiency and preventing overheating, which can lead to downtime and costly repairs.