Empowering Wind Energy

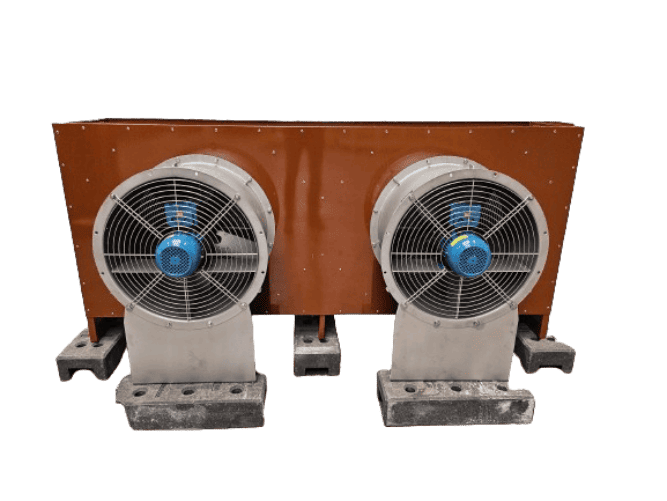

Wind turbine cooling system

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Innovative Wind Turbine Cooling Systems

In the dynamic field of wind energy, the efficiency and longevity of wind turbines are paramount. At ICARUS, we understand that the heart of a wind turbine, the nacelle, houses critical components that generate considerable heat during operation. This heat, if not properly managed, can significantly reduce the lifespan and efficiency of these components. Our innovative cooling solutions are designed to dissipate this heat effectively, ensuring the optimal performance and durability of wind turbines. By leveraging advanced cooling technologies, we provide customized systems tailored to meet the unique needs of each turbine, encompassing generator, nacelle, and converter/transformer cooling. Our commitment to sustainability and efficiency is reflected in our systems, which are engineered to minimize energy consumption while maximizing cooling effectiveness.

Customized Cooling Solutions for Enhanced Performance

At ICARUS, we specialize in creating bespoke cooling solutions that cater to the diverse requirements of industries. Our approach is holistic, considering factors such as turbine size, environmental conditions, and space constraints within the nacelle. Our cooling systems are designed with flexibility in mind, allowing for seamless integration into various turbine models. This adaptability ensures that each system provides optimal cooling, regardless of the turbine’s design or location. By focusing on customized solutions, we ensure that every wind turbine equipped with an ICARUS cooling system achieves superior performance, reduced downtime, and extended service life. Our systems are not only efficient but also robust, capable of withstanding harsh environmental conditions while maintaining consistent cooling performance.

Advancing Wind Energy with our Cooling Technologies

The future of wind energy is bright, and at ICARUS, we are proud to contribute to its advancement with our state-of-the-art cooling systems. Our technologies are at the forefront of the industry, setting new standards for efficiency, reliability, and sustainability. By continuously innovating and improving our cooling solutions, we aim to support the wind energy sector in achieving higher energy production rates and lower lifecycle costs. Our commitment to excellence and our deep understanding of wind turbine cooling requirements make ICARUS the preferred partner for wind energy projects worldwide. Together, we can harness the power of the wind more effectively, paving the way for a greener, more sustainable future.

Request a quotation

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Fill out the details below, and our team will provide a personalized quote to help you harness the power of optimized energy in manufacturing. Step into the future, one quote at a time.

ICARUS Heat Exchangers