EFFICIENCY AND INNOVATION OF ICARUS AIR HEAT EXCHANGERS

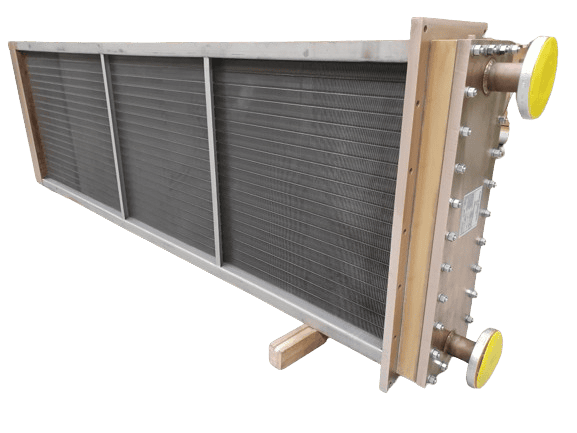

Air Heat Exchanger

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Introduction to Air Heat Exchangers

The Essence of Air Heat Exchangers

Air heat exchangers are pivotal in various industrial and domestic settings, playing an essential role in heating, cooling, and the ventilation of spaces for controlling humidity. They function by transferring heat between two fluids, typically air and a liquid, without mixing them. This process is essential for maintaining optimal temperatures and improving energy efficiency in systems.

Air heat exchangers stand at the forefront of thermal transfer technology. Their design allows for efficient heat exchange, reducing energy consumption and costs. This is especially crucial in settings where maintaining specific temperature conditions is paramount. The key benefits of this type of heat exchangers are:

- Energy Efficiency: By optimizing the heat transfer process, these exchangers significantly lower energy bills.

- Sustainability: With less energy consumption, they contribute to a smaller carbon footprint, aligning with environmental goals.

- Versatility: Suitable for a range of applications, from industrial processes to domestic heating and cooling.

- Low Maintenance: Engineered for durability, they require minimal upkeep, saving time and resources.

Dutch excellence in heat exchange

At ICARUS Heat Exchangers, we blend Dutch craftsmanship with innovative technology, redefining the gold standard for industrial heat exchangers. Dive into the future of sustainable manufacturing, where our Dutch-engineered solutions elevate energy efficiency to unparalleled heights.

Lower total cost of ownership (TCO)

We go beyond performance with our heat exchangers, sculpting an unbeatable blend of.

Direct manufacturer benefits

Your unique needs are our command. We offer tailored heat exchanger solutions.

Customized solutions

With ICARUS Industrial, you're not just buying a product, you're engaging a partnership. Our direct sales model

Superior durability

Built from robust materials, our heat exchangers are a testament to resilience. They reduce maintenance

Redefining Thermal Efficiency with ICARUS

At ICARUS Heat Exchangers, our expertise in Dutch-engineered industrial and electrical heat exchangers is unparalleled. We pride ourselves on delivering products that not only excel in thermal transfer technology but also lead the way in innovative and sustainable solutions. Our commitment to excellence is evident in every aspect of our heat exchangers, from the advanced energy transfer process to the meticulous quality assurance protocols.

Innovative Solutions

Our current design philosophy emphasizes the importance of reducing heat losses while maximizing heat transfer effectiveness. This is achieved through the use of finned tube exchangers and innovative airflow rates, which ensure efficient heat exchangers regardless of the heat source or operating temperature. Our exchangers effectively manage the temperature of air and fluids, maintaining an undisturbed temperature balance essential for various industrial applications.

Sustainable Practices

We are dedicated to sustainable practices, focusing on the recovery of heat and energy efficiency. Our products are designed to provide fresh air ventilation while incorporating improved ventilation techniques. This approach not only contributes to environmental sustainability but also enhances the capacity for energy recovery, especially in systems dealing with exhaust steam or exhaust air.

Quality Assurance

At ICARUS, each heat exchanger is rigorously tested to ensure its durability and reliability. We pay close attention to the thermal contact and cross flow dynamics, ensuring that our exchangers maintain a constant temperature, even under varying ambient air temperatures. The construction types and materials used in our exchangers are chosen for their ability to withstand additional heat loads and maintain efficiency over long periods.

Our exchangers are adept at handling different phases of energy transfer, whether it’s dealing with streams of water or air to air heat exchange. The innovative design of our exchangers allows for efficient exchange ventilation, providing a seamless integration of energy recovery and efficient operation. Our range includes various types of heat exchangers, each tailored to meet specific industry needs, whether it’s managing the inlet air temperature, body temperature in controlled environments, or ensuring efficient use of fresh air in energy recovery systems.

Applications in Various Sectors

Our air exchangers find their place in numerous sectors, including:

- Industrial Processes: Enhancing efficiency in manufacturing and processing industries.

- Electrical Systems: Keeping electrical components at optimal temperatures to prevent overheating.

- Domestic Heating and Cooling: Ensuring comfortable living environments with efficient temperature control.

Why Choose ICARUS?

ICARUS Heat Exchangers are not just products; they are a symbol of engineering excellence and environmental responsibility. By choosing us, you’re opting for a partner who values quality, innovation, and sustainability.

- Cost-Effective: Our exchangers offer long-term savings by reducing energy and maintenance costs.

- Customized Solutions: Tailored to meet the specific needs of your industry.

- Expert Support: Our team provides comprehensive support, from selection to installation and beyond.

By embracing air heat exchangers, industries and individuals can enjoy the benefits of efficient thermal transfer, reduced energy costs, and a move towards a more sustainable future.

Revolutionize Your Industry with ICARUS Heat Exchangers

Our range of heat exchangers is designed to cater to a wide spectrum of industrial applications, ensuring optimal performance under varying operational conditions. Whether you’re involved in heavy-duty industrial processes or delicate temperature-sensitive operations, we provide the reliability and efficiency your industry needs. By integrating our advanced heat exchangers into your systems, you unlock a new level of productivity and sustainability, positioning your business for success in an increasingly competitive and environmentally conscious world.

Why Choose ICARUS?

ICARUS Heat Exchangers are not just products; they are a symbol of engineering excellence and environmental responsibility. By choosing us, you’re opting for a partner who values quality, innovation, and sustainability.

- Cost-Effective: Our exchangers offer long-term savings by reducing energy and maintenance costs.

- Customized Solutions: Tailored to meet the specific needs of your industry.

- Expert Support: Our team provides comprehensive support, from selection to installation and beyond.

By embracing air heat exchangers, industries and individuals can enjoy the benefits of efficient thermal transfer, reduced energy costs, and a move towards a more sustainable future.

Download a sample DWG

Discover precision engineering: Download a sample DWG of our top-notch heat exchangers.

Electro polishing at ICARUS

Transforming Efficiency into Reality

In the fast-paced, ever-evolving world of industry and technology, efficiency isn’t just a goal; it’s a necessity. ICARUS Heat Exchanger types are more than just components in your system; they are catalysts for change, driving your processes towards unparalleled efficiency and reliability. Embrace the future of thermal transfer with our cutting-edge air heat exchanger systems, and experience the difference in every aspect of your operation.

Experience the Power of Innovation

Our Dutch-engineered heat exchangers are a blend of meticulous design and innovative technology. They are not just products; they are a testament to our relentless pursuit of excellence. With ICARUS, you’re not just buying a heat exchanger; you’re investing in a solution that’s tailored to meet the unique demands of your industry. Whether it’s for an industrial giant or a critical electrical system, our exchangers are designed to deliver performance that you can count on.

Sustainable Solutions for a Greener Tomorrow

In a world where sustainability is no longer optional, ICARUS leads the way. Our heat exchangers are designed with the planet in mind, ensuring that your operations are not only efficient but also environmentally friendly. By reducing energy consumption and minimizing carbon emissions, our products help you meet your sustainability goals while maintaining operational excellence.

Why ICARUS is the Smart Choice

- Cost-Effective Operations: Our heat exchangers are engineered to optimize energy use, significantly cutting down your operational costs.

- Tailored to Your Needs: We understand that every industry has unique demands. That’s why we offer customized solutions that perfectly align with your specific requirements.

- Unmatched Quality and Durability: Our commitment to quality means that every ICARUS heat exchanger is built to last, ensuring that your investment pays off for years to come.

- Expert Support and Service: Our relationship with clients goes beyond the sale. We offer comprehensive support, ensuring that your ICARUS experience is seamless and satisfying.

Get in Touch to Improve Efficiency

Step into the future with ICARUS Heat Exchangers. Partner with us and join a growing family of forward-thinking businesses and industries that have chosen efficiency, reliability, and sustainability. With ICARUS, you’re not just improving your operations; you’re setting a new standard for excellence in your field.

Request a quotation

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Fill out the details below, and our team will provide a personalized quote to help you harness the power of optimized energy in manufacturing. Step into the future, one quote at a time.

ICARUS Heat Exchangers

Quotation Form

Frequently Asked Questions about Air Heat Exchangers

As you consider integrating ICARUS Heat Exchangers into your operations, it’s natural to have questions. Here, we address some of the most common inquiries to help you understand how our products can benefit your business.

1. What Makes ICARUS Heat Exchangers Stand Out?

ICARUS Heat Exchangers are renowned for their Dutch-engineered precision, innovative design, and sustainable performance. Our products offer enhanced energy efficiency, exceptional durability, and reduced maintenance needs, setting them apart in the industry.

2. How Do Air Heat Exchangers Improve Energy Efficiency?

Our air heat exchangers are designed to optimize the transfer of heat between air and other mediums with minimal energy loss. This efficient transfer process reduces the overall energy consumption of the system, leading to significant cost savings.

3. Can ICARUS Products Be Customized for Specific Industrial Needs?

Absolutely! We specialize in providing customized solutions tailored to the unique requirements of different industries. Our team works closely with clients to design and manufacture thermal energy exchangers that meet their specific operational needs.

4. Are ICARUS Heat Exchangers Environmentally Friendly?

Yes, our products are engineered with sustainability in mind. By improving energy efficiency and reducing emissions, they contribute to a greener and more sustainable industrial environment.

5. What Types of Industries Benefit from Air Heat Exchangers?

Heat exchangers are versatile and can be used in a wide range of industries, including manufacturing, electrical, automotive, and HVAC systems, among others.

6. How Do Heat Exchangers Handle High-Pressure Applications?

Thermal energy exchangers are designed to withstand high-pressure conditions, ensuring reliable and safe operation in demanding environments.

7. What Maintenance is Required for These Heat Exchangers?

ICARUS Heat Exchangers are designed for low maintenance. However, regular checks and basic cleaning are recommended to maintain optimal performance.

8. How Does ICARUS Support Clients Post-Purchase?

We provide comprehensive support, including installation guidance, operational training, and after-sales service to ensure a smooth experience for our clients.

9. What is the Lifespan of a Heat Exchanger?

Our heat exchangers are built to last. With proper maintenance, they can operate efficiently for many years, providing a long-term solution for your thermal transfer needs.

10. How Quickly Can ICARUS Deliver Custom Heat Exchangers?

Delivery times vary based on customization requirements and production schedules. However, we strive to meet client deadlines with efficiency and promptness.

ICARUS Heat Exchangers are more than just equipment; they are a commitment to excellence, efficiency, and sustainability. If you have more questions or are ready to experience the ICARUS difference, contact us today. Let’s innovate and excel together in the world of thermal transfer technology.