Empowering Oil refineries

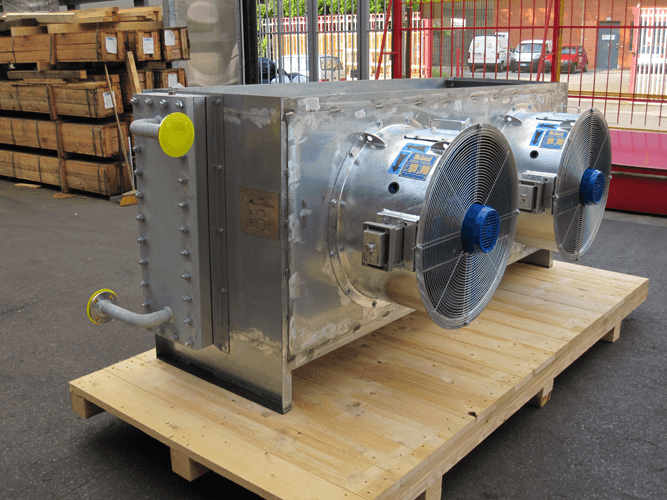

Heat exchanger oil refinery

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Heat Exchanger Oil Refinery

Heat exchangers in oil refineries are pivotal components designed to transfer heat efficiently between two or more fluids—often between a hot process stream and a cooler one—without mixing them. These devices play a critical role in refining crude oil into various usable products such as gasoline, diesel fuel, and jet fuel. By leveraging heat exchangers, refineries optimize energy usage, minimize energy costs, and enhance overall process efficiency. The primary types of heat exchangers used in oil refineries include shell and tube, plate, and air-cooled exchangers, each selected based on their efficiency, cost-effectiveness, and suitability for specific refinery applications. Their operation is essential for distillation processes, crude oil heating, and thermal cracking, making them integral to the operational success and environmental sustainability of oil refineries.

Engineering Efficiency: Unveiling the Core of Refinery Heat Exchange Systems

In the intricate world of oil refining, the mastery of heat exchange technology marks the difference between mere operational functionality and peak efficiency. At the core of this technology lies the heat exchanger, a device that not only conserves energy but also significantly reduces greenhouse gas emissions by optimizing the heat transfer process.

The Role of Heat Exchangers in Refining Processes

Heat exchangers are employed throughout the refinery, from preliminary heating of the crude oil in the atmospheric distillation column to the final stages of product cooling. By transferring heat from hotter to cooler fluids without direct contact, these exchangers help maintain an energy-efficient cycle. This is particularly evident in the crude distillation unit (CDU), where heat exchangers warm the incoming crude oil using the residual heat from the distilled fractions, a process pivotal for enhancing energy affordability and security.

Types and Selection Criteria

Selecting the right type of heat exchanger for a given refinery operation involves a detailed understanding of the fluid properties, the required heat transfer rates, and the environmental conditions. Shell and tube heat exchangers are renowned for their robustness and efficiency in high-pressure environments, making them suitable for heavy-duty applications like hydrocracking. Plate heat exchangers, on the other hand, offer superior heat transfer efficiency and are easier to clean, thus reducing downtime due to fouling—a common issue in oil refineries.

Technological Advances and Environmental Impact

Recent advancements in heat exchanger design, such as the development of compact plate and spiral heat exchangers, have further revolutionized the efficiency of these systems. These innovations not only occupy less space but also provide higher heat transfer coefficients, enabling refineries to meet stringent energy efficiency standards and environmental regulations. Moreover, the integration of smart monitoring systems within heat exchangers enables proactive maintenance strategies, minimizing the risk of unexpected downtime and optimizing heat transfer performance.

The synthesis of these technologies in oil refineries exemplifies how cutting-edge engineering can align with environmental sustainability goals. By reducing fuel consumption and minimizing emissions, heat exchangers contribute significantly to the industry’s efforts in reducing its environmental footprint, demonstrating a commitment to the ideal energy triangle of affordability, security, and environmental stewardship.

Discover Refining Excellence with ICARUS Finned Tube Heat Exchangers

At ICARUS, our expertise in finned tube heat exchangers transforms standard oil refining processes into models of efficiency and sustainability. Recognizing the critical role of heat exchangers in the oil refinery sector, we dedicate ourselves to engineering solutions that not only meet but exceed the demands of modern refineries.

Tailored Solutions for Enhanced Performance

Our finned tube heat exchangers are designed to maximize heat transfer efficiency while minimizing energy consumption and operational costs. By adopting ICARUS heat exchangers, refineries can enjoy significant cost savings and improved operational efficiency—key factors in today’s competitive market. Whether it’s handling the rigorous demands of crude oil heating or optimizing the fractionation process, our heat exchangers are built to deliver unmatched performance.

Invitation to Innovate Together

We invite industry leaders and engineers to explore how ICARUS can elevate your refinery’s heat management systems. With our cutting-edge technology and a commitment to environmental sustainability, partnering with ICARUS means investing in a future where energy efficiency and reduced emissions go hand in hand. Contact us today to learn how our finned tube heat exchangers can revolutionize your refining operations, ensuring that your process units not only thrive in efficiency but also contribute positively to environmental stewardship.

Request a quotation

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Fill out the details below, and our team will provide a personalized quote to help you harness the power of optimized energy in manufacturing. Step into the future, one quote at a time.

ICARUS Heat Exchangers