Welcome to the fascinating world of propylene glycol cooling! ICARUS Industrial, a leading finned tube heat exchanger manufacturer, invites you to explore the advantages and applications of propylene glycol cooling in modern industrial processes.

Table of Contents

Understanding propylene glycol

Propylene glycol is an organic compound widely used for its excellent heat transfer properties. This non-toxic antifreeze is safe for human ingestion, with a sweet taste, and is often used in industries that stand a chance of contact with food, such as the food processing and beverage industry.

In simple terms, it acts as an agent for lubricants and textiles, with a broad application loop in sectors like automotive, agricultural, and even breweries.

The difference between propylene and other glycol compounds

Diving into the benefits of glycol, it’s essential to understand the difference between propylene glycol and other anitfreeze compounds, like ethylene and triethylene glycol. While all types of coolant possess antifreeze properties, their specific applications and safety profiles vary.

Propylene, in particular, is favored for its low toxicity, making it suitable for food industry use and as a food-grade antifreeze. Meanwhile, triethylene coolant has found niche use in industries requiring special additive formulations, but it’s not typically used in common heat transfer applications.

CUSTOMIZED SOLUTIONS

DIRECT MANUFACTURER BENEFITS

LOWER OWNERSHIP COSTS (TCO)

SUPERIOR DURABILITY

Propylene vs. ethylene glycol

Though ethylene glycol also showcases anti-freezing properties, the level of toxicity differs significantly, making propylene coolant a safer alternative, especially in situations where there is a potential for accidental contact. Brands of antifreeze vary, but the aspect of glycol that remains constant is the basic components and physical properties that make it suitable for cooling applications.

The advantage of glycol coolants

Using this type of coolant for process cooling comes with a bundle of advantages. It provides a range of protection against freezing at various temperatures from as low as 14 degrees to 60 degrees, depending on the coolant to water ratio in the mixture of coolant. Its heat transfer capacity and efficiency outpace regular tap water, making it a desirable fluid in heat transfer systems.

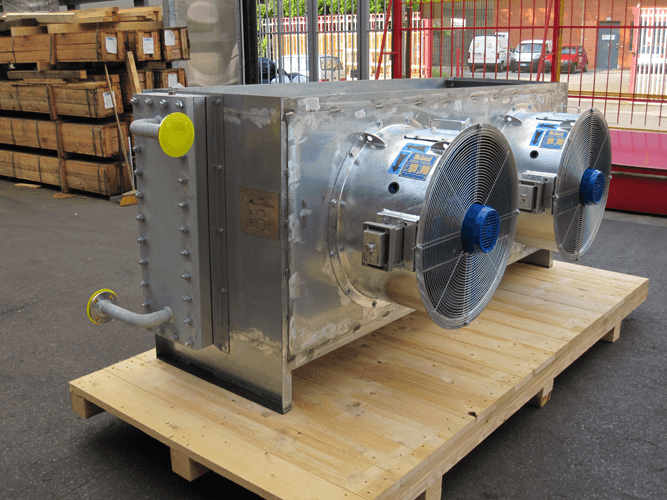

Additionally, with the right additive compatibility and formulations, this type of coolants can offer excellent corrosion resistance, boosting the component life of the equipment it’s used in. ICARUS Industrial’s finned heat exchangers, as an alternative to microchannel designs, utilize these superior heat transfer properties of the antifreeze mixture to provide bespoke, cost-effective cooling solutions.

Contact our expert innovator

Elmer de Goode

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Contact our specilialized team for all your questions.

Propylene glycol cooling in industrial applications

The diverse range of industries using propylene glycol cooling attests to its effectiveness and versatility.

In the automotive industry, it serves as an automotive antifreeze, protecting the engine from freezing in cold weather and overheating in hot conditions. The refrigeration unit in the brewing industry utilizes antifreeze chillers for rapid cooling during the brewing process, ensuring the quality of beer in beer towers.

Additionally, propylene coolant serves as an effective antifreeze in vehicles, helping to maintain the fluid condition irrespective of ambient temperatures.

How to achieve optimal glycol cooling

Achieving optimal glycol cooling requires attention to the proper coolant content, the correct mixture of water, and a compatible inhibitor package.

For instance, a 32% antifreeze to water ratio provides freeze protection down to 14 degrees, while a higher ratio can provide protection even at colder temperatures. The flow rate, the cooling process, and the operating temperature also influence the effectiveness of the glycol-based coolant.

Inhibitors like silicate-based inhibitors and multi-metal and multi-function inhibitors can enhance additive performance, reducing the breakdown of this coolant and extending the life of your cooling system.

Ensuring optimal heat transfer efficiency

The heat transfer efficiency of a coolant solution can be influenced by several factors, including the fluid flow rate, the heat exchange design, and the type of refrigeration system in place. For example, in a closed-loop system, the heat energy is continuously circulated, leading to efficient transfer of heat.

Further, maintaining a proper ratio of water to coolant is critical. Too much antifreeze can lead to a reduction in heat transfer capacity, while too little can leave the system vulnerable to freezing under ambient conditions. ICARUS Industrial offers an online design tool that can help users determine the ideal balance for their specific needs.

Safeguarding against environmental concerns

While glycol offers many benefits, it’s essential to use it responsibly. Brands of antifreeze should ensure their products are formulated with appropriate corrosion inhibitors. Inhibited coolants can resist corrosive elements in the system, extending the lifespan of the machinery, and reducing environmental impact.

A particular application where safety is paramount is aeroplane de-icing. Propylene glycol, with its low freezing point and non-toxic nature, is often used as an anti-freezing agent. Here, ensuring it’s mixed with potable water and rust inhibitors helps mitigate any environmental or equipment damage.

Your ambitions, our mission

Our skilled team at Icarus Information is prepared to convert your event questions into practical solutions. Are you ready to take the next step?

Conclusion

From air conditioning to hot water heating systems, propylene coolant cooling is becoming integral to modern industrial processes. Its versatility, superior heat transfer properties, and safety aspects make it a reliable solution for many industries, especially when used in robust and cost-effective heat exchangers like those manufactured by ICARUS Industrial.

To summarize, the success of propylene glycol cooling hinges on choosing the right type of antifreeze, the proper mixture, and the correct inhibitors. With these factors in place, industries can harness the power of propylene coolant to improve operational efficiency and productivity, making it a true game-changer in the world of industrial cooling.

RELATED ARTICLES

Dehumidification of air

In the realm of industrial efficiency and innovation, ICARUS Heat Exchangers stand as a beacon of excellence, particularly when it comes to the dehumidification of air. This process is crucial in various sectors, including construction, where controlling humidity levels can significantly impact project timelines, material integrity, and ultimately, the overall success of a project. Table

The innovating water to air heat exchanger

At ICARUS Industrial, we’ve been at the forefront of heat exchange innovation, continuously exploring and developing technologies to drive efficiency and sustainability in diverse industries. Today, we’re excited to delve into the world of our latest breakthrough: the innovative water-to-air exchanger. Engineered with meticulous precision and cutting-edge technology, this game-changing device optimizes the transfer of

Is propylene glycol cooling the industrial game-changer?

Welcome to the fascinating world of propylene glycol cooling! ICARUS Industrial, a leading finned tube heat exchanger manufacturer, invites you to explore the advantages and applications of propylene glycol cooling in modern industrial processes. Table of Contents Understanding propylene glycol Propylene glycol is an organic compound widely used for its excellent heat transfer properties. This

How heat exchange systems transform the energy usage

Welcome to the world of heat exchange systems, where energy efficiency and innovative technology transform the way industries use and manage energy. ICARUS Industrial is at the forefront of this revolution, with our robust finned heat exchangers. We provide bespoke, cost-effective solutions with direct manufacturer benefits, setting us apart in the industry. Table of Contents