Improve processing with heat exchangers

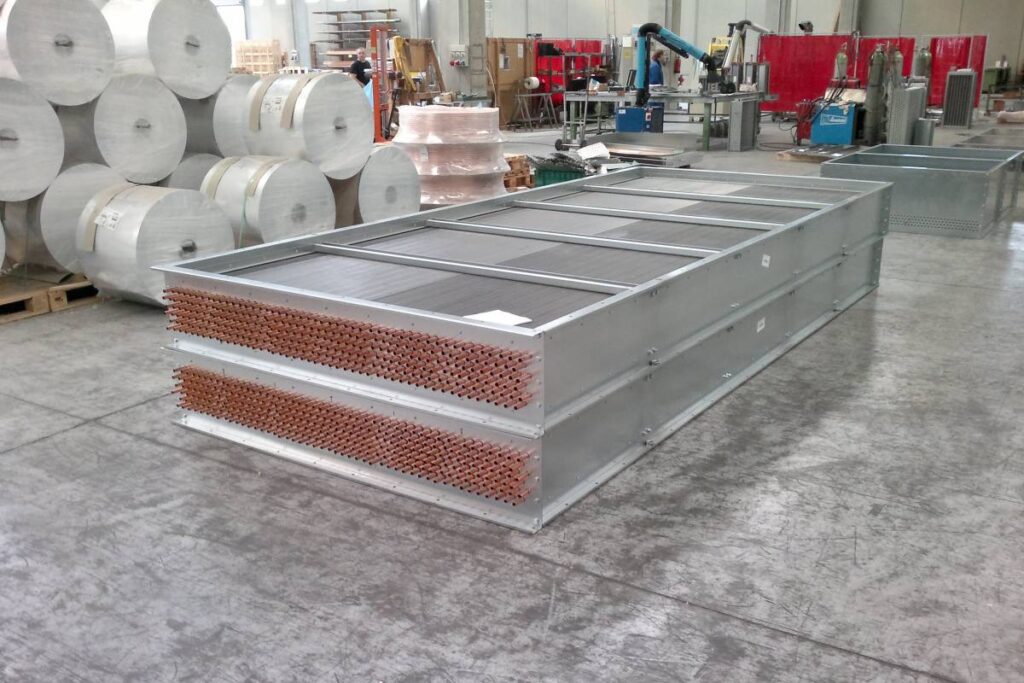

Custom Stainless Steel Heat Exchanger

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Precision-Built Solutions for Demanding Thermal Challenges

A Custom Stainless Steel Heat Exchanger is a tailored thermal system designed to meet specific industry, process, and pressure requirements. Unlike off-the-shelf options, these units are engineered from stainless steel materials to deliver efficient heat transfer, exceptional corrosion resistance, and long-term durability in environments with extreme temperatures, pressures, or caustic applications. Whether the need is for a shell and tube, plate type, or air-cooled configuration, custom designs ensure optimized heat exchange capacity, control of quality, and performance across power generation, commercial refrigeration, and chemical processing systems.

Shaped by Need: Where Design Precision Meets Industrial Purpose

In a world where thermal performance defines operational success, off-the-shelf simply isn’t enough. That’s why ICARUS crafts every custom stainless steel heat exchanger as a reflection of its purpose—carefully designed, rigorously tested, and optimized for function. From compact evaporators for space-saving installations to robust U-tube shell & tube heat exchangers for high-pressure systems, our units are the result of decades of experience, precise tooling, and relentless attention to detail.

Engineered to Fit: Tailored Configurations and Applications

Every process tells its own story—be it space heating, mobile oil cooling, or complex chemical process industry needs. At ICARUS, our design team evaluates your project’s unique requirements, offering solutions across a comprehensive range of heat exchanger types: from plate heat exchangers and brazed plate units to 8-pass shell & tube heat exchangers. Each unit is built with custom fittings, optimized port sizes, and precise tool machining—ensuring that both the internal flow and external exchanger configuration fit seamlessly within your operation.

Material Mastery: Stainless Steel and Beyond

Selecting the right material is more than a technical decision—it’s a commitment to longevity and safety. Our exchangers are fabricated from 316L stainless steel, known for its superior corrosion resistance, especially in caustic or closed-loop heating systems. For high-performance needs, we offer alloy materials and carbon steel shells with stainless steel tube bundles, ideal for balancing thermal demands and cost analysis. Whether it’s crevice corrosion or high contact time environments, our materials are proven to endure.

Built for Inspection, Built to Last

True performance is measured over time. That’s why every ICARUS unit is designed with maintenance and time evaluation in mind. From entire tube bundle access to Quickmill Intimidator-machined tolerances, we ensure that every component is built to withstand extreme pressure and rigorous service inspections. And with configurations like double tubesheet designs or vertical reboilers, we accommodate a wide array of commercial applications while ensuring your system runs flawlessly—time after time.

Download products reference list

Download the comprehensive product reference list for heat exchangers and cooling systems.

Dutch excellence in heat exchange

Customized solutions

With ICARUS Industrial, you're not just buying a product, you're engaging a partnership. Our direct sales model

Direct manufacturer benefits

Your unique needs are our command. We offer tailored heat exchanger solutions.

Lower total cost of ownership (TCO)

We go beyond performance with our heat exchangers, sculpting an unbeatable blend of.

Superior durability

Built from robust materials, our heat exchangers are a testament to resilience. They reduce maintenance

Let’s Build the Heat Exchanger That Fits Your Vision

When standard isn’t enough, ICARUS delivers custom stainless steel heat exchangers engineered around your reality. From carbon steel steam shells to tube bundles with exceptional corrosion resistance, we specialize in quality custom builds that align with your project proposal, design requirements, and performance goals.

Whether you’re working on a chiller solution, cool petroleum products, or need a unit built for extreme pressure and a specific square foot surface area, our team provides custom engineering, complimentary concept evaluations, and reliable support from concept to commissioning.

Contact ICARUS today and discover how our custom stainless steel heat exchangers can transform your thermal systems into long-term, efficient, and resilient solutions.

Request a quotation

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Fill out the details below, and our team will provide a personalized quote to help you harness the power of optimized energy in manufacturing. Step into the future, one quote at a time.

ICARUS Heat Exchangers

Quotation Form

FACTS ABOUT ICARUS

> 27

With over 27 years in business, we’ve carved out a reputation for excellence and innovation.

> 120+

Our global presence is marked by a diverse clientele of over 120 customers worldwide.

> 850+

Moreover, our portfolio boasts more than 850 completed projects.

FAQs about Custom Stainless Steel Heat Exchanger

What makes a shell & tube heat exchanger ideal for power generation?

Shell & tube heat exchangers are preferred in power generation due to their durability under extreme pressure and high-temperature environments. Custom configurations such as 8-pass U-tube designs allow for superior heat exchange capacity, while robust tube bundles ensure reliability and efficiency over extended cycles.

How does a brazed plate heat exchanger differ from a plate type heat exchanger?

A brazed plate heat exchanger offers a compact size and sealed construction, making it ideal for commercial refrigeration applications and closed loop heating systems. In contrast, plate type heat exchangers are easier to disassemble for cleaning, making them suitable for processes requiring frequent maintenance and inspection.

What is the importance of crevice corrosion resistance in custom heat exchangers?

Crevice corrosion can severely damage internal surfaces in systems with poor fluid distribution or stagnant areas. By selecting corrosion-resistant stainless steel solutions and utilizing double tubesheet design or smooth surface machining, ICARUS ensures long-term protection in chemical process and food-grade applications.

Can I request custom fittings and service nozzles in my heat exchanger design?

Yes, ICARUS offers fully customizable options including MNPT fittings, service nozzles, and ample port sizes to ensure seamless integration with your existing system. These features are essential for industrial process equipment where precision and adaptability are key to operational success.

How does ICARUS ensure control of quality in custom stainless steel heat exchanger manufacturing?

Our commitment to control of quality includes advanced manufacturing tools like the Quickmill Intimidator, tight tolerance machining, and full inspection of exterior surfaces and welds. This results in robust designs that meet the highest industry standards, even in commercial applications with demanding conditions.