Improve processing with heat exchangers

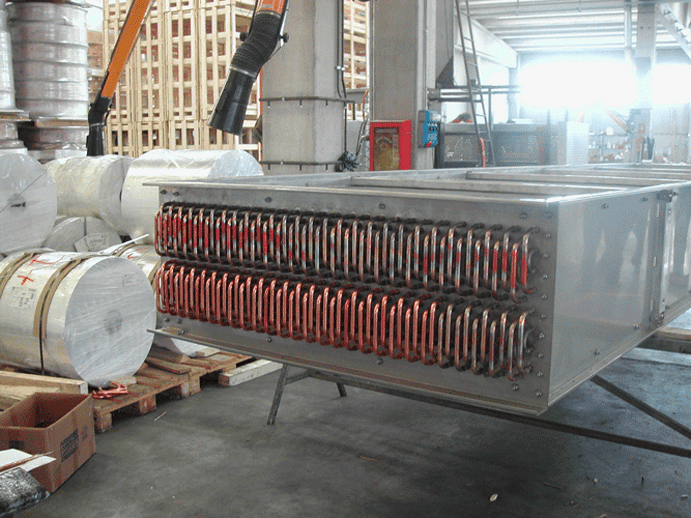

Heat Exchanger for Plastic Recycling

Elevating global standards with exceptional, unmatched Dutch craftsmanship in advanced industrial heat exchange.

Understanding What a Heat Exchanger for Plastic Recycling Is

A Heat Exchanger for Plastic Recycling is a thermal system designed to manage heat transfer during polymer processing, pyrolysis, and chemical recycling. It efficiently recovers and redistributes heat generated when converting plastic waste into reusable raw materials such as monomers, ethylene glycol, or styrene. Built from stainless steel or high-temperature alloys, these exchangers maintain stable process temperatures in reactors, drying systems, and condensers. By optimizing thermal control, they improve energy efficiency, reduce emissions, and enhance the overall performance of plastic recycling plants, ensuring sustainable and cost-effective material recovery across industrial operations.

Optimizing Thermal Efficiency in Plastic Recycling

Managing Heat in Recycling Processes

A Heat Exchanger for Plastic Recycling plays a crucial role in stabilizing temperatures during pyrolysis, depolymerization, and chemical recycling. These processes require precise thermal control to convert plastic waste into reusable compounds such as ethylene, propylene, and terephthalic acid. By recovering heat from reactors, distillation columns, or drying systems, ICARUS heat exchangers improve energy efficiency while maintaining steady process conditions. This ensures higher conversion yields and reduces fuel consumption across polymer recycling plants.

Durable Engineering for High-Temperature Operations

ICARUS designs every heat exchanger using stainless steel, nickel alloys, and other materials that resist corrosion and high temperatures typical in chemical recycling. Each system is built for continuous operation in polymer reactors, steam generation, or gas-phase pyrolysis, where temperature stability is essential for consistent quality. The use of plate and shell and tube configurations allows for easy maintenance, optimal heat transfer, and adaptability to different process requirements.

Reducing Energy Loss and Improving Process Safety

Thermal management directly affects both safety and performance in recycling environments. ICARUS heat exchangers recover waste heat and repurpose it for preheating raw feedstock, drying plastic flakes, or maintaining reactor conditions. This reduces the plant’s energy consumption and carbon footprint while ensuring safe operating temperatures. Additionally, every unit can integrate with safety instrumented systems and monitoring controls to provide reliable, real-time thermal management.

Supporting Sustainable Polymer Recovery

By optimizing heat transfer efficiency, ICARUS systems enable recycling companies to convert complex polymer-based materials into high-quality secondary raw materials. Whether processing polyolefins, PET, or mixed plastic films, our exchangers contribute to cleaner operations and long-term sustainability. The result is a robust, low-maintenance system that supports efficient material recovery and extends the lifecycle of valuable resources.

Download products reference list

Download the comprehensive product reference list for heat exchangers and cooling systems.

Dutch excellence in heat exchange

Customized solutions

With ICARUS Industrial, you're not just buying a product, you're engaging a partnership. Our direct sales model

Direct manufacturer benefits

Your unique needs are our command. We offer tailored heat exchanger solutions.

Lower total cost of ownership (TCO)

We go beyond performance with our heat exchangers, sculpting an unbeatable blend of.

Superior durability

Built from robust materials, our heat exchangers are a testament to resilience. They reduce maintenance

Partnering with ICARUS for High-Performance Plastic Recycling Systems

At ICARUS Heat Exchange Group, we design Heat Exchangers for Plastic Recycling that deliver precise thermal control, exceptional energy efficiency, and long-term reliability. Each system is tailored for demanding environments such as pyrolysis plants, chemical recycling facilities, and polymer processing lines.

Our exchangers are constructed from durable stainless steel and nickel alloys, ensuring resistance to high temperatures and aggressive process gases. ICARUS technology improves heat transfer efficiency, reduces energy waste, and enhances overall plant productivity. Contact our engineering team today to learn how our industrial heat exchangers can optimize your recycling operations and support sustainable plastic recovery.

Request a quotation

Elevate your efficiency with Dutch-engineered solutions tailored for your needs. Fill out the details below, and our team will provide a personalized quote to help you harness the power of optimized energy in manufacturing. Step into the future, one quote at a time.

ICARUS Heat Exchangers

Quotation Form

FACTS ABOUT ICARUS

> 27

With over 27 years in business, we’ve carved out a reputation for excellence and innovation.

> 120+

Our global presence is marked by a diverse clientele of over 120 customers worldwide.

> 850+

Moreover, our portfolio boasts more than 850 completed projects.

FAQs about Heat Exchanger for Plastic Recycling

What is the purpose of a Heat Exchanger in plastic recycling?

A Heat Exchanger for Plastic Recycling manages thermal energy during pyrolysis, chemical recycling, and polymer processing. It transfers heat between process streams to maintain stable temperatures, recover waste heat, and improve energy efficiency throughout the recycling plant.

What types of heat exchangers are used in plastic recycling plants?

Common configurations include plate, shell and tube, and air-cooled heat exchangers. The choice depends on the specific process, such as reactor heating, condensate cooling, or vapor recovery, ensuring reliable heat transfer performance under high-temperature conditions.

How do heat exchangers improve the efficiency of plastic recycling systems?

By recovering waste heat from hot gases, condensate, or vapor streams, ICARUS exchangers reduce energy consumption and fuel demand. This boosts thermal efficiency, lowers operating costs, and supports more sustainable recycling operations.

What materials are used in heat exchangers for recycling applications?

ICARUS manufactures exchangers from stainless steel, nickel alloys, and other high-performance metals that resist corrosion and withstand the high temperatures and aggressive chemicals typical of polymer recycling environments.

Why choose ICARUS for Heat Exchangers for Plastic Recycling?

ICARUS Heat Exchange Group designs advanced industrial heat exchangers built for long service life and consistent performance. Our systems integrate precise temperature control, high heat transfer efficiency, and energy recovery to support modern plastic recycling plants focused on sustainability and productivity.